Top 10 Benefits of Using APIs in Manufacturing for Efficiency and Innovation

In today’s rapidly evolving manufacturing landscape, the adoption of technology plays a pivotal role in enhancing operational efficiency and fostering innovation. The integration of APIs in manufacturing is reshaping how industries function by enabling seamless communication between systems, which is crucial for data-driven decision-making. According to a report by McKinsey, companies adopting digital solutions, including APIs, have seen a 20-30% increase in production efficiency and a significant reduction in operational costs. This highlights the importance of leveraging API in manufacturing for optimizing workflows and driving tangible results.

Moreover, the International Data Corporation (IDC) predicts that by 2025, 65% of organizations will have adopted industry cloud platforms that heavily rely on APIs to bridge existing technologies and facilitate real-time data exchange. By implementing API strategies, manufacturers can enhance their agility and responsiveness to market demands, leading to improved product development cycles and customer satisfaction. In an environment characterized by increasing competition and complexity, the strategic use of API in manufacturing not only accelerates innovation but also provides a sustainable path toward long-term growth.

Overview of APIs in Manufacturing and Their Role in Efficiency

APIs, or Application Programming Interfaces, play a vital role in the manufacturing sector by enhancing operational efficiency and fostering innovation. The manufacturing industry is currently witnessing a significant digital transformation, with a report by McKinsey indicating that companies that effectively utilize APIs can increase their operational efficiency by up to 30%. This efficiency is largely attributable to the seamless connectivity that APIs provide between machinery, software systems, and supply chains, allowing for real-time data exchange and automation of processes.

Moreover, APIs facilitate innovation by enabling manufacturers to integrate new technologies with existing systems. According to a study by PwC, manufacturers that adopt API strategies can rapidly prototype and deploy new solutions, significantly reducing time-to-market for new products by as much as 50%. This agility not only enhances productivity but also positions companies to respond swiftly to market changes and customer demands. By leveraging the power of APIs, manufacturers are not only streamlining operations but also embracing a culture of continuous improvement and innovation, crucial for staying competitive in today's fast-paced industrial landscape.

Key Benefits of API Integration for Streamlining Operations

In the rapidly evolving manufacturing sector, API (Application Programming Interface) integration has emerged as a pivotal tool for streamlining operations. By allowing different software systems to communicate seamlessly, APIs enhance data sharing and reduce manual inputs, leading to improved efficiency. Through API connectivity, manufacturers can automate workflows, minimize errors, and ensure real-time data synchronization across various platforms, resulting in quicker decision-making and enhanced productivity.

Tips for successful API integration include thoroughly assessing current workflows and identifying bottlenecks that could benefit from automation. Additionally, investing in the right API management tools can simplify monitoring and scaling, which is essential for adapting to changing production demands. It is also crucial for manufacturers to establish clear communication between IT and operational teams, ensuring that integration strategies align with overall business goals.

Incorporating APIs into manufacturing processes not only boosts operational efficiency but also fosters innovation. By enabling easier access to third-party services and platforms, manufacturers can explore new technologies and solutions. This adaptability allows for the rapid incorporation of advancements such as IoT and AI, further driving operational improvements and transforming traditional manufacturing practices into smart, connected processes.

Enhancing Innovation through API-Driven Data Sharing

In the fast-evolving landscape of manufacturing, the integration of Application Programming Interfaces (APIs) is becoming a cornerstone for driving innovation. According to a report by ResearchAndMarkets, nearly 70% of manufacturing companies are focusing on digital transformation initiatives, with data sharing and collaboration at the forefront. API-driven data sharing enables manufacturers to connect disparate systems, allowing for real-time information exchange. This capability enhances decision-making processes and fosters an environment where innovation can thrive, as teams can leverage accurate data insights to develop new products and improve existing ones.

Furthermore, a study by McKinsey highlights that companies utilizing APIs can accelerate their product development cycles by up to 30%, owing to more streamlined communication and decreased reliance on manual processes. By facilitating seamless interaction between machines, software, and stakeholders, APIs not only enhance operational efficiency but also encourage the adoption of smart manufacturing technologies. For instance, manufacturers can integrate IoT devices through APIs, leading to advanced analytics that predict equipment failures before they occur, ultimately driving technological advancements and streamlining production workflows. This level of innovation, powered by API-driven data sharing, positions manufacturers to respond agilely to market demands, creating a more resilient and forward-thinking industry.

Top 10 Benefits of Using APIs in Manufacturing for Efficiency and Innovation

Improving Collaboration and Communication with APIs

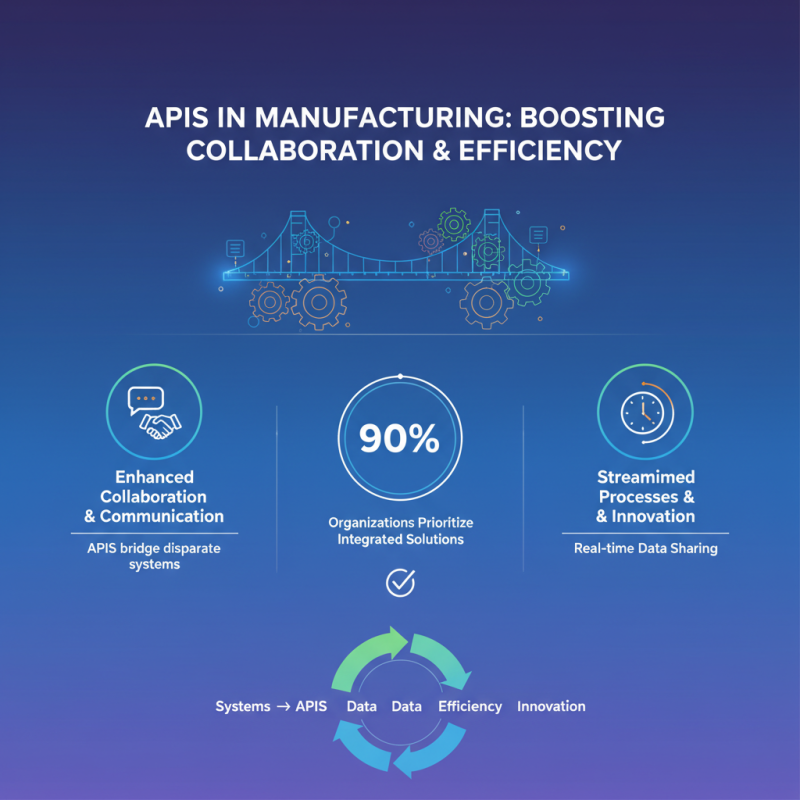

In the realm of manufacturing, leveraging APIs has become paramount for enhancing collaboration and communication. APIs serve as a crucial bridge, enabling disparate systems to interact seamlessly, thus fostering a more interconnected environment. According to recent industry reports, nearly 90% of organizations recognize the significance of integrated communication solutions, illustrating how essential APIs are for modern operations. By facilitating real-time data sharing and communication, manufacturers can streamline processes and improve efficiency, ultimately driving innovation.

Furthermore, the rise of solutions like Unified Communications as a Service (UCaaS) exemplifies the transformative impact of APIs on business collaboration. As organizations increasingly adopt UCaaS—positioned as a cornerstone of business communication—APIs allow manufacturers to unify their communication channels, enhancing teamwork and project management. Reports suggest that companies utilizing these integrated platforms experience a marked improvement in productivity, as teams can communicate more effectively, irrespective of their geographical locations. This shift redefines how manufacturing enterprises approach collaboration in an era that demands agility and responsiveness, underscoring the vital role of APIs in shaping the future of efficiency and innovation.

Real-World Examples of Successful API Implementation in Manufacturing

In the realm of manufacturing, the implementation of APIs has ushered in significant advancements in both efficiency and innovation. For instance, a leading automotive manufacturer harnessed APIs to synchronize its supply chain management system with real-time inventory data. This integration allowed them to optimize production schedules, reduce lead times, and respond swiftly to market demands, resulting in a notable increase in operational efficiency. By connecting various software applications through APIs, manufacturers can maintain seamless communication across departments, enhancing collaboration and decision-making.

Another compelling example comes from a prominent electronics manufacturer that utilized APIs to integrate its customer relationship management (CRM) system with its production line. This enabled the team to gather customer insights directly from the sales channels and adjust production runs accordingly. By understanding customer preferences and adjusting outputs in real time, the manufacturer not only minimized waste but also tailored products to meet market needs more effectively. Such applications of APIs demonstrate their vital role in fostering a more agile and innovative manufacturing landscape.

Top 10 Benefits of Using APIs in Manufacturing for Efficiency and Innovation

| Benefit | Description | Implementation Example | Efficiency Gain |

|---|---|---|---|

| Improved Data Integration | APIs allow different systems to share data seamlessly. | Connecting supply chain management systems. | 30% faster data availability. |

| Increased Flexibility | Easier to adapt to new market demands. | Rapidly scaling production lines. | 20% reduction in lead times. |

| Cost Savings | Reduce costs through automation and optimized processes. | Automating order management. | 15% decrease in operational costs. |

| Enhanced Collaboration | Facilitates teamwork between different departments. | Integrating R&D with manufacturing. | 25% faster project delivery. |

| Real-Time Data Access | Immediate insights into production metrics. | Dashboard for live production monitoring. | 35% improvement in response times. |

| Scalability | Easy to scale operations as demand grows. | Adding new machines or production lines. | 40% growth management capability. |

| Innovation Facilitation | APIs promote development of new solutions. | Creating advanced analytics features. | 65% increase in new product development. |

| Improved Customer Experience | Personalized offerings to customers. | Custom order portals. | 30% increase in customer satisfaction scores. |

| Enhanced Security | Secure environments for data exchange. | Implementing secure API gateways. | 50% reduction in data breach incidents. |

Related Posts

-

Ultimate Guide to Selecting the Best Pharmaceutical Processing Equipment for Your Needs

-

The Future of API Manufacturing Innovations Driving Global Supply Chain Efficiency

-

What is the Impact of Advanced Pharma Equipment on Global Drug Production Efficiency

-

Understanding the Role of API in Pharmaceutical Industry Innovation and Development

-

How to Optimize API Pharmaceutical Development for Maximum Efficiency

-

Maximizing Efficiency in API Manufacturing with Digital Strategies and Key Industry Insights