Ultimate Guide to Selecting the Best Pharmaceutical Processing Equipment for Your Needs

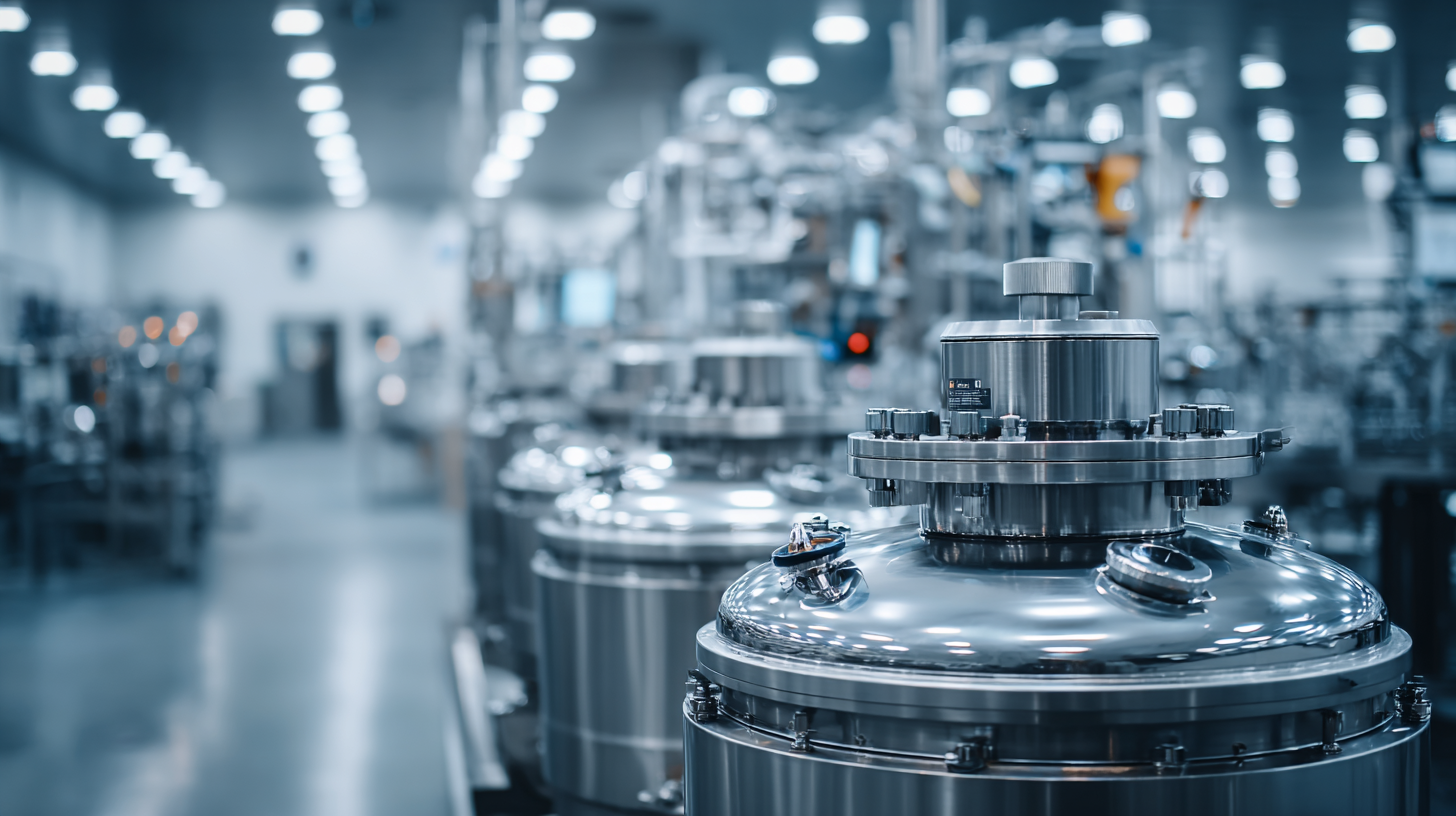

When it comes to the pharmaceutical industry, the choice of pharmaceutical processing equipment can significantly impact product quality, safety, and compliance with regulatory standards. With an overwhelming array of options available, selecting the right equipment tailored to your specific needs can be a daunting task. This ultimate guide aims to simplify the selection process by providing key considerations, insights, and best practices for choosing the most suitable pharmaceutical processing equipment.

From understanding the various types of equipment to evaluating factors such as efficiency, scalability, and cost-effectiveness, our comprehensive approach will equip you with the knowledge necessary to make informed decisions. Whether you are looking to upgrade existing systems or invest in new machinery, this guide will serve as an essential resource for ensuring that your pharmaceutical processes are both efficient and compliant with industry standards.

Understanding Your Pharmaceutical Processing Equipment Needs

Selecting the right pharmaceutical processing equipment begins with a thorough understanding of your specific needs. Every pharmaceutical facility has unique requirements based on the types of products being manufactured, regulatory compliance, and production volume. Take the time to analyze your processes and identify the key factors that impact your operational efficiency. This ensures that the equipment you choose supports your production goals and complies with industry standards.

**Tip 1:** Conduct a comprehensive assessment of your current processes. Determine bottlenecks, inefficiencies, and areas that require improvement. This will help you identify equipment that can streamline your manufacturing workflow.

Another crucial aspect is considering the scalability of your equipment. As your business grows, so too will your processing demands. Ensure that the equipment you select can adapt to increased production without significant modifications or additional investments.

**Tip 2:** Look for equipment that offers flexibility and modularity. This will allow you to easily integrate new technologies or additional functionalities in the future, keeping you competitive in the fast-evolving pharmaceutical landscape.

Pharmaceutical Processing Equipment Selection Criteria

This chart illustrates the importance rating of various criteria considered when selecting pharmaceutical processing equipment. Cost, efficiency, reliability, compliance, and scalability play crucial roles in decision-making, with compliance being the highest-rated factor.

Key Factors to Consider When Choosing Equipment

When selecting pharmaceutical processing equipment, it's essential to consider several key factors to ensure that you meet your specific needs efficiently. First and foremost, assess the compatibility of the equipment with your existing processes. This includes understanding the materials being processed and ensuring that the equipment can handle them without compromising quality or safety.

Tip: Always opt for equipment that offers flexibility in size and functionality. This adaptability allows for future modifications or upgrades without requiring a complete overhaul of your current system.

Another critical factor is the equipment's regulatory compliance. The pharmaceutical industry is highly regulated, and failure to comply can lead to serious consequences. Ensure that the equipment meets the necessary standards set by regulatory bodies, which will not only protect your business but also enhance credibility among clients and partners.

Tip: Stay informed about the latest regulatory advancements and standards in the pharmaceutical sector to ensure your equipment remains compliant with evolving requirements. This proactive approach can save you time and costs associated with retrofitting or replacing non-compliant equipment.

Lastly, consider the long-term support and availability of spare parts for the equipment you choose. Opting for reputable manufacturers that offer robust support services can significantly minimize downtime and maintenance costs, ideally leading to a more efficient production process.

Comparative Analysis of Different Equipment Types

When it comes to pharmaceutical processing, selecting the right equipment is crucial for efficiency and compliance. A comparative analysis of different equipment types can highlight their unique benefits and help you make informed decisions. For instance, batch processing equipment is ideal for small-scale production, offering flexibility and ease of use. This allows manufacturers to easily switch between product lines, which is ideal for companies that produce a variety of pharmaceuticals.

On the other hand, continuous processing equipment is designed for high-volume production and can significantly enhance productivity by minimizing downtime. By integrating automation and real-time monitoring, these systems ensure consistent product quality while reducing labor costs. Additionally, the use of advanced technology, such as inline blending and real-time analytics, allows for greater control over the manufacturing process, making it an attractive option for large pharmaceutical companies that prioritize efficiency and scalability. Each equipment type has its advantages, and understanding these differences is key to optimizing your pharmaceutical operations.

Best Practices for Equipment Maintenance and Optimization

When it comes to pharmaceutical processing equipment, maintenance and optimization are crucial components that can significantly impact operational efficiency and overall output. Implementing best practices for maintenance not only extends the life of equipment but also ensures compliance with industry regulations. Regular inspections, timely upgrades, and training for personnel are essential strategies that can help identify potential issues before they escalate, ensuring uninterrupted production and adherence to quality standards.

Moreover, leveraging technology can enhance optimization efforts. For instance, adopting predictive maintenance using real-time data analytics can aid in foreseeing equipment failures and scheduling maintenance at the most convenient times, thereby minimizing downtime. Another critical aspect is the efficiency of energy use, which can be optimized through innovative practices aimed at reducing the environmental footprint of operations.

By focusing on these maintenance and optimization strategies, pharmaceutical companies can improve their operational efficiency while aligning with sustainability goals, ultimately driving better performance in a competitive market.

Regulatory Compliance and its Impact on Equipment Selection

When selecting pharmaceutical processing equipment, regulatory compliance plays a pivotal role in ensuring that the equipment meets the stringent safety and quality standards required in the industry. Understanding the basic regulatory science behind drug specifications, such as those for monoclonal antibodies and protein therapeutics, is essential for pharmacists and manufacturers alike. The specifications outline critical attributes that the equipment must adhere to in order to facilitate safe and efficient production processes, thereby significantly influencing the equipment selection process.

In addition, the evolving landscape of regulations, such as those related to sustainability and digital manufacturing, has an impact on how equipment is chosen and implemented. For instance, the adoption of Industry 4.0 technologies for risk management in pharmaceutical production highlights the need for equipment that not only meets regulatory standards but can also adapt to innovative practices. As regulatory frameworks continue to change, staying informed about these developments is crucial for stakeholders looking to invest in pharmaceutical processing equipment that will withstand the test of time and regulatory scrutiny.

Ultimate Guide to Selecting the Best Pharmaceutical Processing Equipment for Your Needs - Regulatory Compliance and its Impact on Equipment Selection

| Equipment Type | Key Features | Regulatory Compliance | Considerations for Selection |

|---|---|---|---|

| Tablet Press | Automated operation, variable speed, integrated tooling | FDA, ISO 9001 | Capacity, material compatibility, ease of cleaning |

| Granulator | Adjustable speed, efficient size reduction | GMP, CE mark | Power consumption, by-product management, ease of maintenance |

| Blender | Homogeneous mixing, adjustable time settings | FDA, EHEDG | Capacity, material finishes, cleanliness |

| Filling Machine | Accurate dosage, versatility for various containers | ISO 13485, 21 CFR Part 11 | Automation level, calibration performance, product changeover |

| Sterilizer | Temperature monitoring, steam and dry heat options | FDA, ISO 11135 | Cycle time, validation protocols, user safety |